Nishimatsu Construction Co., Ltd. announced on the 9th that it has developed a system that can instantly confirm the arrival of concrete piles to the support layer with greater accuracy when constructing cast-in-place concrete piles by soil drilling method. In addition to the conventional method based on visual inspection by field engineers, excavator vibration visualization data, which varies depending on ground stiffness, will also be used to determine whether whether the support layer has been reached or not. We will apply the newly developed system to real sites and try to further improve its reliability.

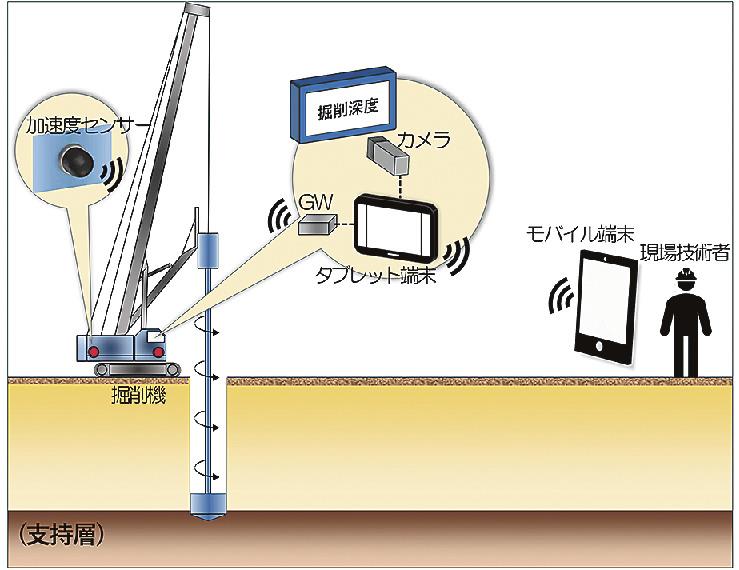

Outline of development system (from press release document)

To confirm that cast-in-place concrete piles have reached the support layer by soil drilling, the field engineer often compares the soil and sand collected during excavation with samples taken during the preliminary drilling survey by testing. Visual investigation. However, it is rare for samples to be available at all pile locations and there is a concern that field engineers may misjudge the occurrence of subsoil support where mid-layer soil changes occur. support and the top part of the support layer is small.

Nishimatsu Construction has developed a system that uses excavator vibration as a more accurate confirmation method to supplement visual confirmation of arrival at the support layer. Wireless accelerometers attached to the vehicle's body measure the intensity of vibrations, which vary depending on the hardness of the ground. Next, we created an "acceleration index" based on the measured data to use as a benchmark to access the support layer and visualize the relationship between ground depth and vibration intensity. It also uses depth information obtained through image processing from the display of the depth gauge mounted on the driver's seat, making it possible to instantly generate and display a depth distribution of the same reading.

Finally, the relationship between the depth distribution of this index and the “N value”, which represents the stiffness and compaction of the soil obtained in the pre-excavation drilling survey, is determined by pile construction Firstly. Based on the information obtained at that time and the change in depth distribution of the same index, it is determined whether the second and subsequent piles have reached the bearing layer.

The system is compatible with many excavator models. Field technicians can instantly monitor measurement results on their mobile devices.

Invite partners to see the activities of Pacific Group Co., Ltd.

FanPage: https://www.facebook.com/Pacific-Group

YouTube: https://www.youtube.com/@PacificGroupCoLt