Nishimatsu Construction and ONESTRUCTION (Tottori City, president: Ohho Nishioka), a company that develops solutions in the construction sector, will streamline and optimize the placement of temporary equipment at construction sites Build a tunnel in the mountain. We use ``creative design'', a system that automatically generates various design proposals by entering images and design requirements into the computer. This system incorporates the know-how and ideas that Nishimatsu Construction has cultivated through tunnel construction. We are also building a system to convert veterans' tacit knowledge into explicit knowledge and pass it on to the next generation.

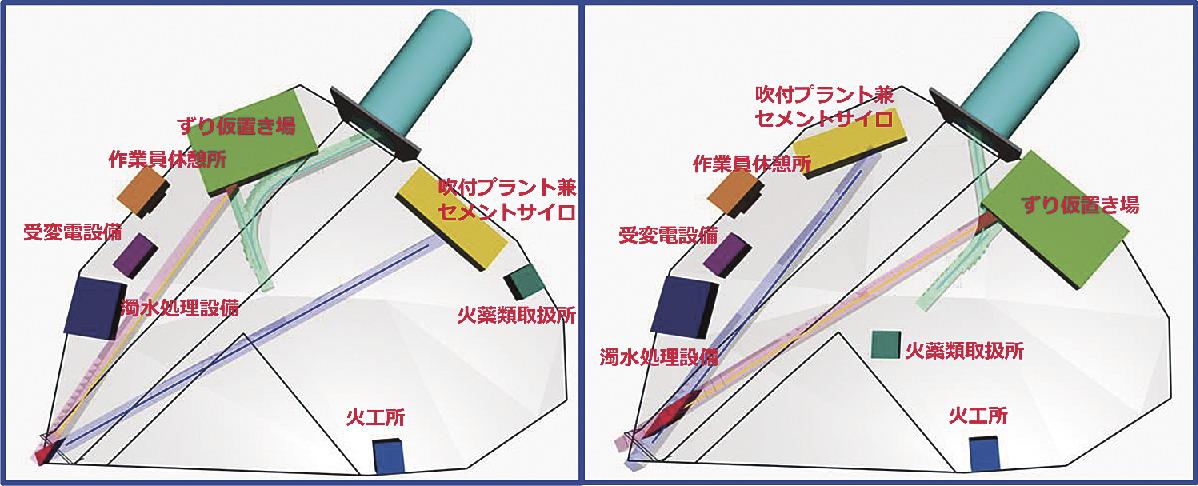

Example of design ideas generated by Generative Design (from press release documents)

It was announced on the 18th. According to Nishimatsu Construction, many temporary equipment are often placed at mountain tunnel construction sites. It is necessary to arrange them optimally and efficiently within the limited space of the construction site, while keeping safety in mind. However, due to having to consider many different factors such as terrain, vehicle routes and ensuring safe passage, even experienced engineers find it difficult to come up with an optimal and effective layout plan. effective, and at the same time it takes a considerable amount of time for young engineers.

Therefore, we focus on system superiority. Reflects the know-how and ideas necessary to rationalize and optimize temporary equipment placement that Nishimatsu Construction has cultivated as tacit knowledge. Engineers efficiently search for and generate optimal designs from a large number of system-generated design proposals, taking into account design goals, functionality, space conditions, materials, etc. materials, manufacturing methods, etc. It offers various benefits, such as streamlining the design review process to comply with regulations on overtime limits and reducing design costs . The effectiveness has been confirmed in practice.

In the future, the company will incorporate the tacit knowledge accumulated in this field into the system and use it to further improve performance. We look forward to further expanding its use in other types of work and as a recommendation tool at the early stages of a project. This will help reduce the time needed to review construction plans, improve the quality of construction management and improve safety management.

Invite partners to see the activities of Pacific Group Co., Ltd.

FanPage: https://www.facebook.com/Pacific-Group

YouTube: https://www.youtube.com/@PacificGroupCoLt