Kajima et al. / First application of carbon-negative concrete formwork, further reducing CO2 emissions

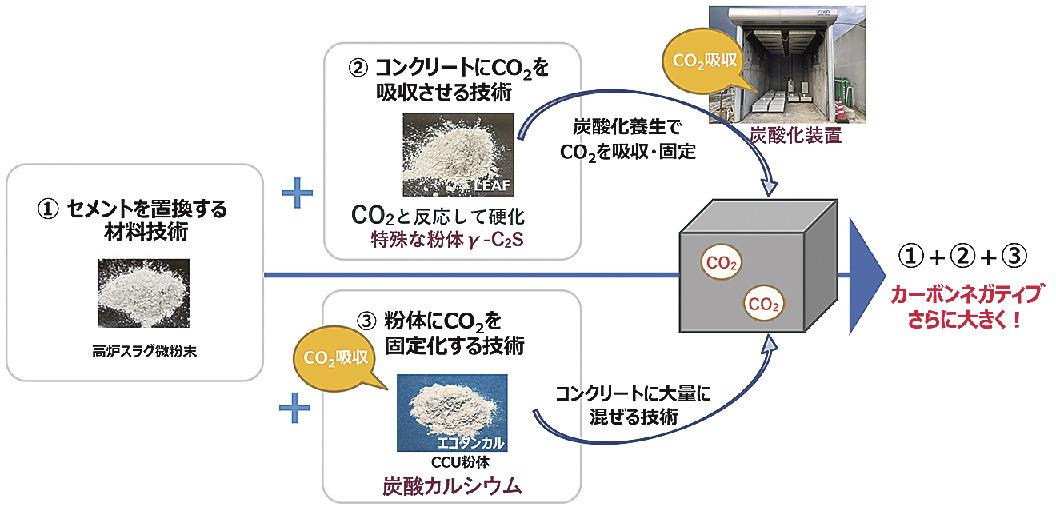

Overview of CUCO-SUICOM formwork (from press release materials)

Kajima announced on the 16th that it had developed the "CUCO-SUICOM Formwork" (CUCO-SUICOM Formwork), which utilizes carbon negative concrete that emits less than zero carbon dioxide (CO2) during the manufacturing process. By improving the CO2-fixing concrete "CO2-SUICOM", we have made it possible to further reduce CO2 emissions. It was first applied to a tunnel construction site as an embedded formwork, and it was confirmed that the amount of CO2 reduction exceeded the amount of emissions.

Implemented as part of the Green Innovation Fund project adopted by the New Energy and Industrial Technology Development Organization (NEDO) by the consortium "CUCO" formed by Kajima (secretary company), Denka, and Takenaka Corporation. This formwork is the first result of CUCO's technological development.

Concrete used for the same formwork is based on two technologies: CO2-SUICOM ▽ Replacing part of the cement with industrial by-products to reduce CO2 ▽ Carbonation curing using a special admixture to absorb and fix CO2 in concrete. , CCU (CO2 capture and storage) powder, calcium carbonate. This maximizes the amount of CO2 reduction and fixation.

The same formwork is used for the first time as a formwork for a drainage channel tunnel in the "Fiscal Year 2020 Kusaka River New Discharge Channel Management Road Construction Project" (ordered by Shikoku Regional Development Bureau, Ministry of Land, Infrastructure, Transport and Tourism), which Kajima will construct in Hidaka Village, Kochi Prefecture. did. 116 forms are used. Replacing cement with industrial by-product granulated blast furnace slag, which is a material of concrete, reduces CO2 emissions by 409 kilograms per cubic meter. In addition, a special admixture and calcium carbonate were used to absorb and fix 268 kilograms of CO2 per cubic meter.

A total of 677 kilograms of CO2 has been reduced. When using a general high-strength panel, 615 kg of CO2 is emitted, but the same formwork has reduced all of them and realized minus 62 kg (62 kg of CO2 absorption).

In the future, CUCO will work together to develop and improve CO2 reduction and fixation technologies.