Ando Hazama và Nishio T&M (Thành phố Takatsuki, tỉnh Osaka, Chủ tịch: Shunsuke Kita) đã cùng phát triển công nghệ thi công bê tông phun tự động nhằm nâng cao năng suất và an toàn khi xây dựng đường hầm trên núi. Điều này đạt được bằng cách giới thiệu ba chương trình: ▽ Thu thập hồ sơ khuôn mặt, xử lý tính toán thông tin vị trí và điều khiển thủy lực. Người vận hành có thể tự động thi công bê tông phun bằng cách vận hành máy tính bảng gắn vào máy phun. Nó dự kiến sẽ được áp dụng cho địa điểm đường hầm trên núi do Ando Hazama xây dựng vào năm 2024.

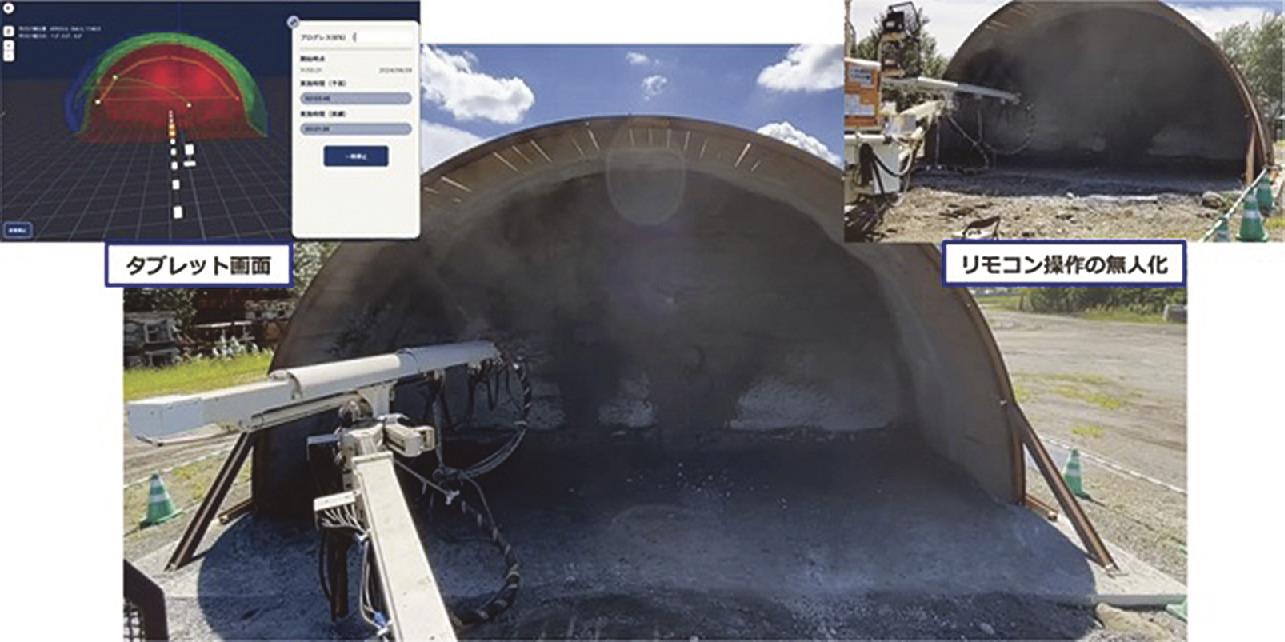

Trạng thái trình diễn trong đường hầm mô phỏng (từ tài liệu thông cáo báo chí)

Chứng minh bằng cách sử dụng một đường hầm mô phỏng. Người ta xác nhận rằng một loạt chức năng như tính toán lượng bê tông phun cần thiết, thi công tự động và xác định độ dày sau khi thi công đều hoạt động như mong đợi.

Trong ba chương trình tạo nên công nghệ mới, chương trình thu thập hình dạng hoàn thiện bề mặt sẽ tính toán lượng bê tông phun cần thiết dựa trên dữ liệu 3D của bề mặt thu được bằng LiDAR lắp đặt phía trước máy phun. Độ dày của bê tông phun được xác định từ sự khác biệt giữa dữ liệu 3D trước và sau khi thi công và hình thức hoàn thiện được xác nhận.

Chương trình xử lý tính toán thông tin vị trí chọn phạm vi thi công bê tông phun từ dữ liệu 3D thu được từ chương trình thu thập hình dạng hoàn thiện bề mặt và tính toán lộ trình của vòi phun để thi công tự động. Hơn nữa, vị trí mục tiêu của đầu vòi phun được xác định, góc và vị trí của vòi phun được kiểm soát.

Chương trình điều khiển thủy lực xác định phạm vi có thể phun được dựa trên thông tin vị trí của đầu vòi phun được xác định bởi chương trình xử lý tính toán thông tin vị trí và thực hiện điều khiển thủy lực của robot phun. Bằng cách thêm một van điện từ tỷ lệ vào mạch thủy lực của máy phun và thay đổi công suất đầu ra từ bộ điều khiển, tốc độ và hành trình của bộ truyền động, chuyển đổi năng lượng thành chuyển động tịnh tiến hoặc quay cơ học, sẽ được điều khiển.

Hazama Ando hiện đang thúc đẩy phát triển ``Hệ thống quản lý đào tích hợp đường hầm núi (i-NATM),'' sử dụng CNTT để tăng đáng kể năng suất và độ an toàn của việc xây dựng đường hầm trên núi. Công ty đặt mục tiêu xây dựng đường hầm trên núi hoàn toàn không cần người điều khiển trong tương lai.

Mời các đối tác xem hoạt động của Công ty TNHH Pacific Group.

FanPage: https://www.facebook.com/Pacific-Group

YouTube: https://www.youtube.com/@PacificGroupCoLt