Researchers at the Franhoufer Institute for Solar Energy Systems (ISE) are working on a means for generating hydrogen directly from seawater, without the need for a desalination plant or similar technology. Instead, the water is desalinated using residual heat from the electrolyser.

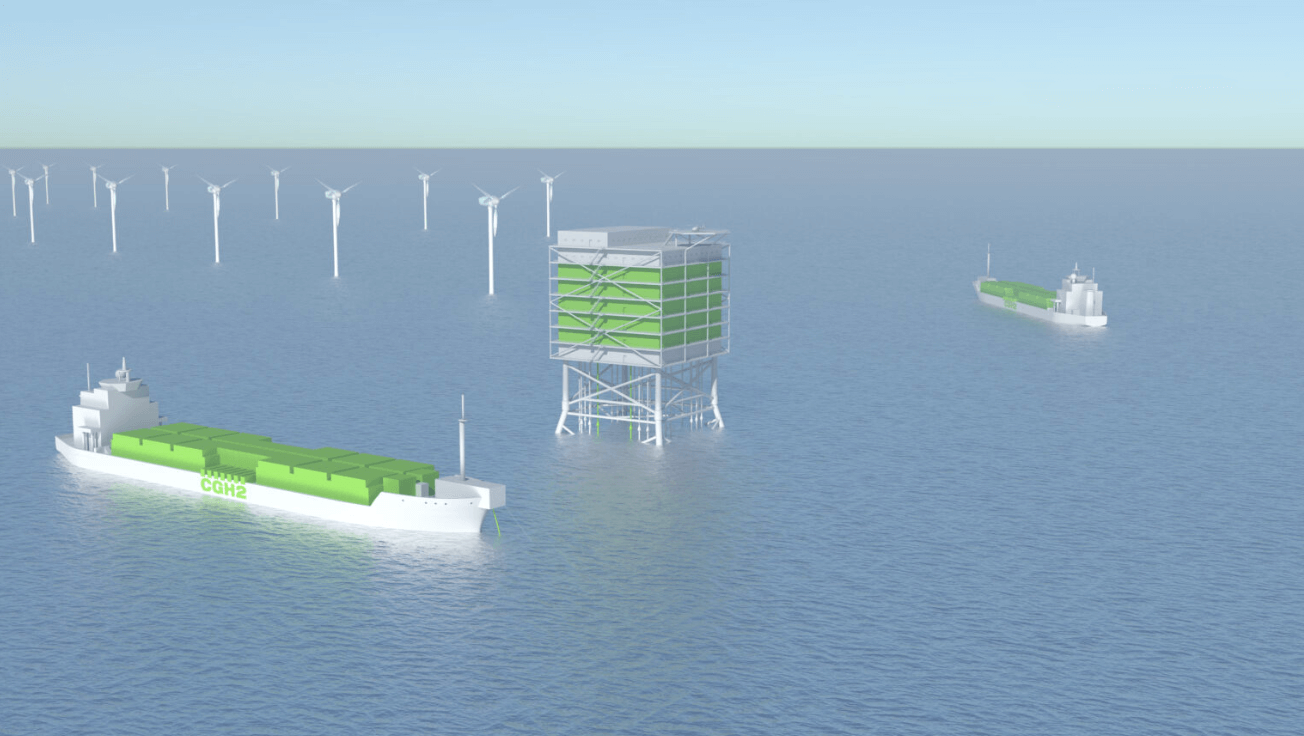

The new hydrogen plant is optimised for offshore operation, and is tied in with a 500 MW windfarm to provide green energy to a proton exchange membrane (PEM) electrolyser and a system for compressing the hydrogen gas generated so it can be transported to land.

It is estimated that the platform will be able to produce up to 50,000 tonnes of green hydrogen per annum.

The resulting hydrogen is dried, purified, and then compressed and sent by pipe to a transport vessel that can carry 400 tonnes of hydrogen to the mainland. Not being tied to a fixed pipeline gives the ultimate flexibility in location.

Marius Holst, the project coordinator explained, “Offshore hydrogen production offers the opportunity to cover the entire value chain at the national level while decoupling the expansion of offshore wind energy and the expansion of the grid.”

Hydrogen production costs increase, and full charge hours decrease with lower wind capacity. For example, a wind farm with a capacity of 490 MW results in hydrogen production costs of €6.37 ($10.63)/kg and full load hours of around 4,225 h/a. As a result of the lower wind capacity, the 500 MW electrolysis is significantly oversized and can no longer operate at a nominal load.

The consortium that worked on the project included Fraunhofer ISE, PNE AG as project coordinator, SILICA Verfahrenstechnik GmbH, KONGSTEIN GmbH, and Wystrach GmbH.