Sumitomo Osaka Cement, Fukuoka University and Chuo Kankyo Kaihatsu (Kanazawa Ward, Yokohama City, President: Toshinori Ota) developed a soil reclamation material using waste gypsum board. It can reform sludge like sludge and is highly resistant to re-sedimentation. Vegetation and greening can keep the soil neutral. Another feature is that compared to conventional neutral modifiers, the amount required to achieve the same performance is only about 1/5, and when the entire construction and operation phase is included, the amount of carbon dioxide (CO2 ) is released less than conventional materials. The amount will be reduced by about 85%. We aim to sell it this year.

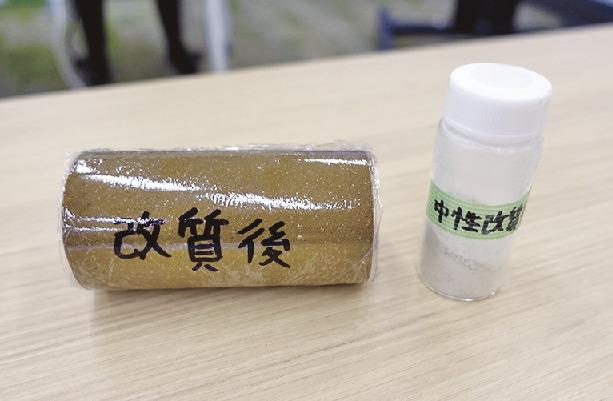

Image of soil improvement materials (right) and improved soil quality

Sumitomo Osaka Cement and other companies held a press conference in Tokyo on the 21st and made an announcement. It exhibits high durability through a chemical reaction using aluminum oxide minerals. More than 80% of the composition is recycled dihydrate plaster, made from recycled gypsum board from demolition waste. When adding 50 kg per cubic meter, a strength of 1000 kilonewtons (N) per square meter can be obtained, equivalent to Class 2 improved soil. The strength can be increased by increasing the amount added. Compared with conventional neutral modified materials whose main ingredient is hemihydrate gypsum, the durability is said to be eight times greater.

It is envisaged that this system will be applied to construction soil, mud, dredged soil, etc., and it will be transported after reclamation or used as fill material, backfill material or material cover.

The company has two production facilities in Kanto and Kansai. Price has not yet been determined but is expected to be around 50,000 to 100,000 yen per ton, and sales in the first year are expected to be 500 million yen. This is part of Sumitomo Osaka Cement's efforts towards carbon neutrality (CN).