From Plastic to Pure Water: Scientists Turn Trash Into a Super Catalyst

By Nagoya Institute of Technology

November 13, 2025

Multifunctional Composite Catalysts for Highly Efficient Water Remediation

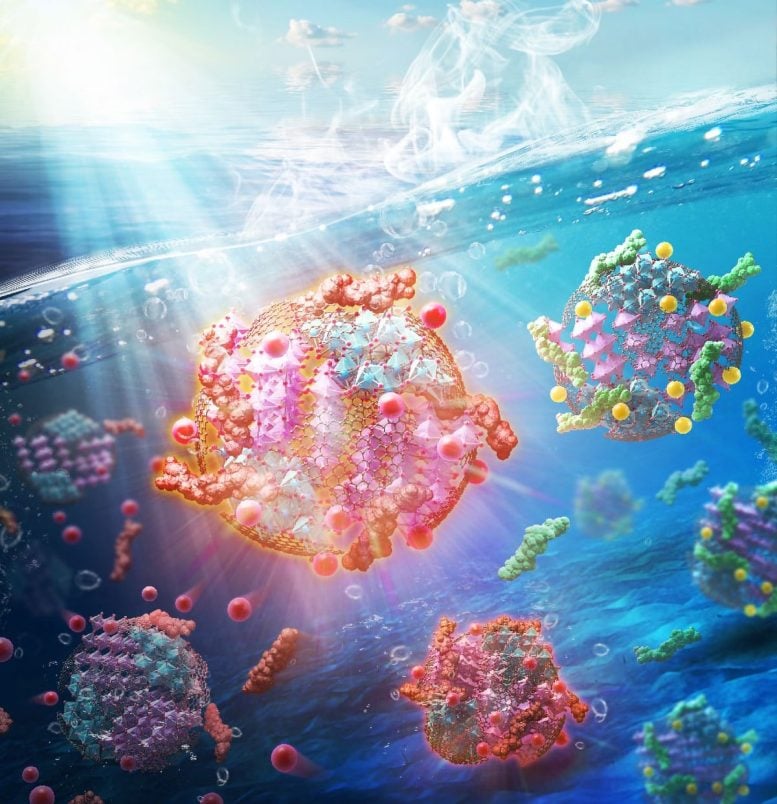

A new class of composite particles made from plastic waste is showing extraordinary promise for producing clean water. These hydrogen molybdenum bronze–molybdenum dioxide/carbon particles demonstrate high photothermal evaporation efficiency, broad-spectrum photocatalytic activity for removing organic pollutants, and strong adsorption capacity for heavy metals—even in total darkness. Their low cost and multifunctionality make them strong candidates for scalable water purification technologies.

Turning Waste Into a Catalyst

Scientists have long recognised sunlight as a powerful tool for cleaning polluted water. Photocatalysts convert sunlight into chemical reactions that break down contaminants, while photothermal materials use solar energy to rapidly heat and evaporate water, leaving impurities behind. However, most current materials are expensive or difficult to produce, limiting real-world deployment.

Researchers at the Nagoya Institute of Technology (NITech) in Japan have now developed an innovative solution that uses plastic waste as the starting material. Led by Associate Professor Takashi Shirai, the team (Dr. Kunihiko Kato, Dr. Yunzi Xin, and Yuping Xu) has created multifunctional composite particles capable of purifying and desalinating water using sunlight alone.

Their findings were recently published in ACS Applied Materials & Interfaces.

Mechanochemical Synthesis Using a Planetary Ball Mill

The research team produced their novel material using planetary ball milling, an energy-efficient mechanochemical process. They combined molybdenum trioxide (MoO3) with polypropylene, a common household and industrial plastic.

Through controlled milling, this mixture was transformed into composite particles containing:

-

Hydrogen molybdenum bronze (HxMoO3–y)

-

Molybdenum dioxide (MoO2)

-

Activated carbon

These components work synergistically to absorb sunlight across the UV–visible–NIR spectrum and trigger multiple purification mechanisms.

“The proposed mechanochemical process surpasses other current approaches in terms of both energy efficiency and cost-effectiveness,” said Dr. Shirai.

Multiple Functions in One Material

Tests showed that the composite particles:

-

Absorb light across a broad spectrum for photocatalytic degradation of organic contaminants

-

Act as Brønsted acid catalysts, enabling pollutant removal even without light

-

Exhibit plasmonic behaviour, generating strong photothermal heating under sunlight

-

Provide adsorption sites (via oxygen-containing carbons) for removing heavy metal ions

This combination allows the same material to break down pollutants, desalinate water, and remove toxic metals.

Toward Scalable Clean Water Solutions

The team plans to refine their ball-milling technique to create other multifunctional catalysts using various plastics and oxide materials.

“Our developed technology can be applied to a wide range of oxides and plastics,” Dr. Shirai explained. “We anticipate diverse applications, including enhancing the functionality of existing materials and upcycling waste plastics to help secure access to clean drinking water.”

Reference: “Multifunctional HxMoO3–y–MoO2/Carbon Composite Particles for Water Remediation” by Kunihiko Kato, Yunzi Xin, Yuping Xu and Takashi Shirai, ACS Applied Materials & Interfaces, 1 October 2024.

DOI: 10.1021/acsami.4c09169