Ten years have passed since the introduction of the Charge-in Tariff (FIT) system. One problem that is likely to become a problem in the future is the deterioration of electrical air conditioners. It's time to consider inverter replacement to prevent breakdowns and maximize power generation. We asked Ampt Japan why.

Avoiding Sudden Inverter Failure "Replace Diagnostic Check"

"The power conditioner (inverter) is broken, so I'm thinking about replacing it." Recently, Ampt Japan is receiving more and more urgent requests from solar power generation companies. When asked about cases, when sales staff asked the air conditioner manufacturer to repair the capacity, they received answers such as "It will take three to six months" and "The model production has been discontinued and will take time to repair." Generation will stop while it is idle, resulting in reduced revenue.

To prevent such a situation, it is possible to replace the inverter before it fails. There are four checkpoints during the replacement period.

If even one of these occurs, you should consider replacing it with a new electric air conditioner. You never know when it will break, and even if it does, you may not be able to fix it. You should be proactive and think about replacement before a breakdown occurs.

Power generation efficiency increased by 10% when used with optimizer !?

In 2012, the electricity input tariff (FIT) system started operating. As the inverter was installed at that time closer to the 10th anniversary, the number of consultations like the one at the beginning increased.

There are two main reasons for recommending early replacement of air conditioners. The first is that the cost of overhauling an inverter can be higher than that of a new inverter. Second, newer ones are better. Energy conditioning technology has made great strides in the past ten years. The new model has much higher conversion efficiency from direct current to alternating current, making it difficult for power generation to be stopped even in low sunlight conditions.

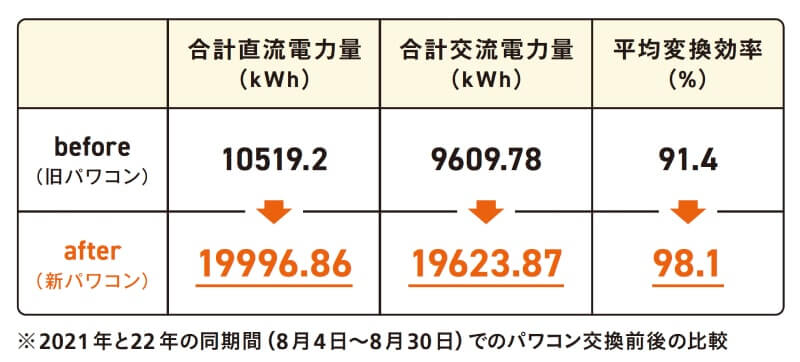

Comparison table of power consumption and power generation efficiency before and after replacing the old inverter with a new one. Power generation efficiency increased by more than 6% from a year ago. Depending on the case, power generation efficiency can increase by 6-10% for a system that has been in use for 5-10 years.

The top photo is an example of a factory in Shizuoka Prefecture that frequently had problems with the power conditioner on the roof of a solar power system. Looking at the average conversion efficiency data of the inverters, in August 2012, the conversion efficiency of the older inverters dropped to 91.4%. When replaced with a new energy conditioner, the conversion efficiency increased to 98.1%.

The conversion efficiency varies depending on the weather and the amount of solar radiation. Older inverters may stop generating power when solar irradiance is low and conversion efficiency may drop to 70-80%. On the other hand, even with low solar radiation, the latest inverters maintain conversion efficiency in the upper half of the 30% range. As a result, there is a big difference in average conversion efficiency per month.

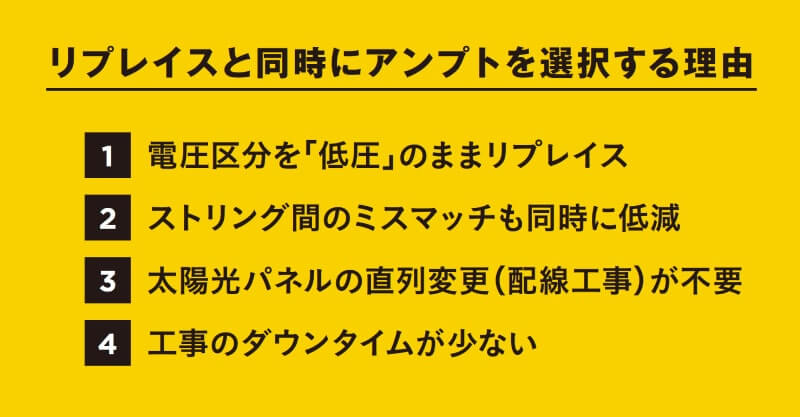

Then just replace the inverter, but that alone is not enough. The DC side voltage of inverters has increased recently. For example, the 144 solar panels in a 600V inverter need to be converted to 20 strings in the latest 1000V inverter. New wiring was required for that purpose, while material and labor costs increased. In addition, if the number of series is increased, it will legally change from low voltage to high voltage, requiring dielectric strength testing, etc., and potentially lead to changes changed as more stringent testing standards. in costly and time-consuming changes.

Simultaneously with the replacement of the power conditioner, if we add the DC-DC converter "Amplification String Optimizer" to obtain the maximum output of all strings, then the inverter can be used. Latest 1000V power conditioner with panel remaining in 1/4 series. .

It is also possible to reduce mismatch losses due to changes in the optimal operating point between wires due to degradation over time. By replacing the power conditioner and introducing the Ampt series optimizer, we can expect a 6-10% increase in power generation. Therefore, even with high replacement costs, power plants in the era of high FIT prices can pay back in about 3 to 5 years.

The government also intends to take a deeper look at maximizing the use of existing renewable energy facilities and turning them into a long-term energy source. For that reason, I would like you to consider replacing the air conditioner unit.