Toda Construction First in Japan to Apply Basalt Rods for Shield Tunnel Temporary Wall Cutting — Lower Cost with Over Twice the Tensile Strength of Steel

October 6, 2025 – Technology & Products

-

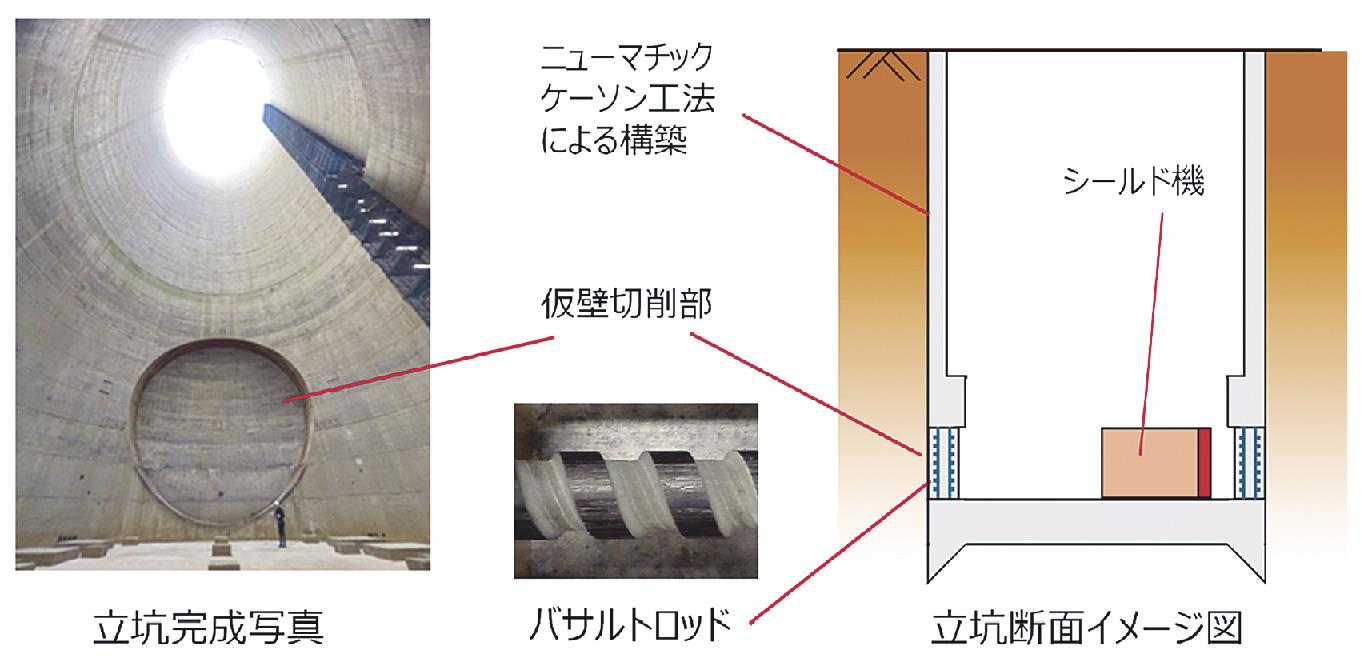

立坑完成写真 → Completed shaft photo

-

ニューマチックケーソン工法による構築 → Constructed by pneumatic caisson method

-

仮壁切削部 → Temporary wall cutting section

-

バサルトロッド → Basalt rod

-

シールド機 → Shield machine

-

立坑断面イメージ図 → Shaft cross-section image

Toda Construction has become the first in Japan to apply basalt rods—reinforcing materials made from inorganic fibers derived from basalt rock—for cutting temporary walls in shield tunnel construction. These rods possess more than double the tensile strength of steel, while being significantly more cost-effective compared to carbon fiber and glass fiber materials. The technology was adopted for a shaft excavation on the Linear Chuo Shinkansen project, reaching a depth of about 110 meters—one of the deepest pneumatic caissons in Japan—with installation now completed.

Basalt rods are manufactured by melting basalt rock at high temperatures to form fibers, bundling them together, and curing with epoxy resin that provides superior alkali resistance. Their surfaces are roughened to enhance adhesion with concrete. In addition to straight forms, the rods can be processed into 90-degree and 180-degree hook shapes. Cutting tests with shield machines confirmed that basalt rods deliver performance equal to or exceeding that of carbon fiber rods.

The shaft reinforced with basalt rods will later serve as an emergency exit for the Linear Chuo Shinkansen. Temporary walls in shield tunnel launch and arrival shafts require both high pressure resistance and reliable cuttability. While carbon fiber rods have excellent performance, their high cost has been a challenge. Toda Construction regards basalt rods as a new material that balances economic efficiency with stable supply, and plans to actively promote their use in future tunnel projects.