Taisei Corporation Automates measurement of mountain tunnel B using LPWA radio, greatly improving safety and productivity

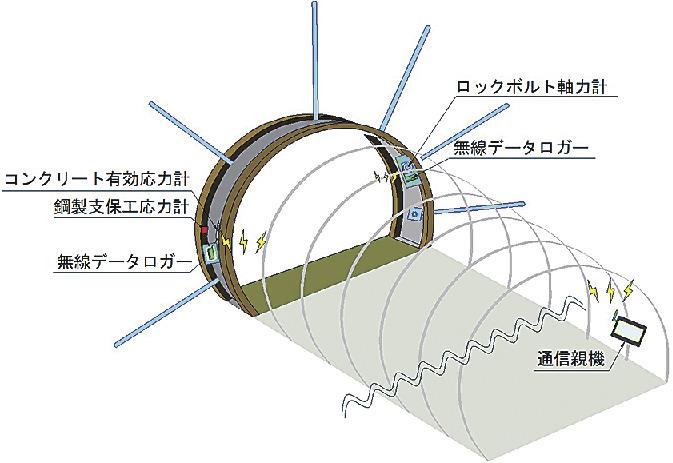

System configuration of "T-RIPPA BK" (provided by Taisei Corporation)

Taisei Corporation has developed a system that can automatically measure various measurements (B measurement) to evaluate the stability of mountain tunnel construction and the standard validity of support members without cables. It consists of a small LPWA wireless data logger, a measuring instrument, and a communication base unit that can communicate over a wide area with low power consumption. It supports multiple channels and can efficiently obtain various measurement data without external power supply. The work time can be reduced by about 70% compared to the conventional wired method, and safety is greatly improved.

The automatic measurement system "T-RIPPA BK" is an improvement of the mountain tunnel underground measurement system "T-RIPPA" that was developed in 2020 to evaluate the ground in front of the face. Multi-channel and compact and integrated wireless data logger corresponding to B measurement that confirms the standard validity of support members (sprayed concrete, rock bolt, steel support).

All measuring equipment and wireless data loggers are installed in advance within 1 meter of the measurement point and the shotcrete is placed. It can be installed safely and efficiently because there is no need for complicated work such as cable wiring and protective work for each device.

The measuring equipment can be operated continuously for one year with only the built-in small battery. Measured data can be communicated by LPWA radio up to a distance of about 1 km inside the tunnel. The company is said to be the first company to fully apply LPWA to measurement work in mountain tunnels.

In a demonstration experiment that was conducted for more than a month during the current construction work, we continuously measured data for a total of 10 channels and confirmed that stable data transfer was possible. The work time required for installing the measuring equipment was shortened by about 70% compared to the conventional method of installing power sources and communication cables. Since the cost is about the same as the conventional method, the plan is to adopt the system for mountain tunnel construction nationwide where B measurement is performed.