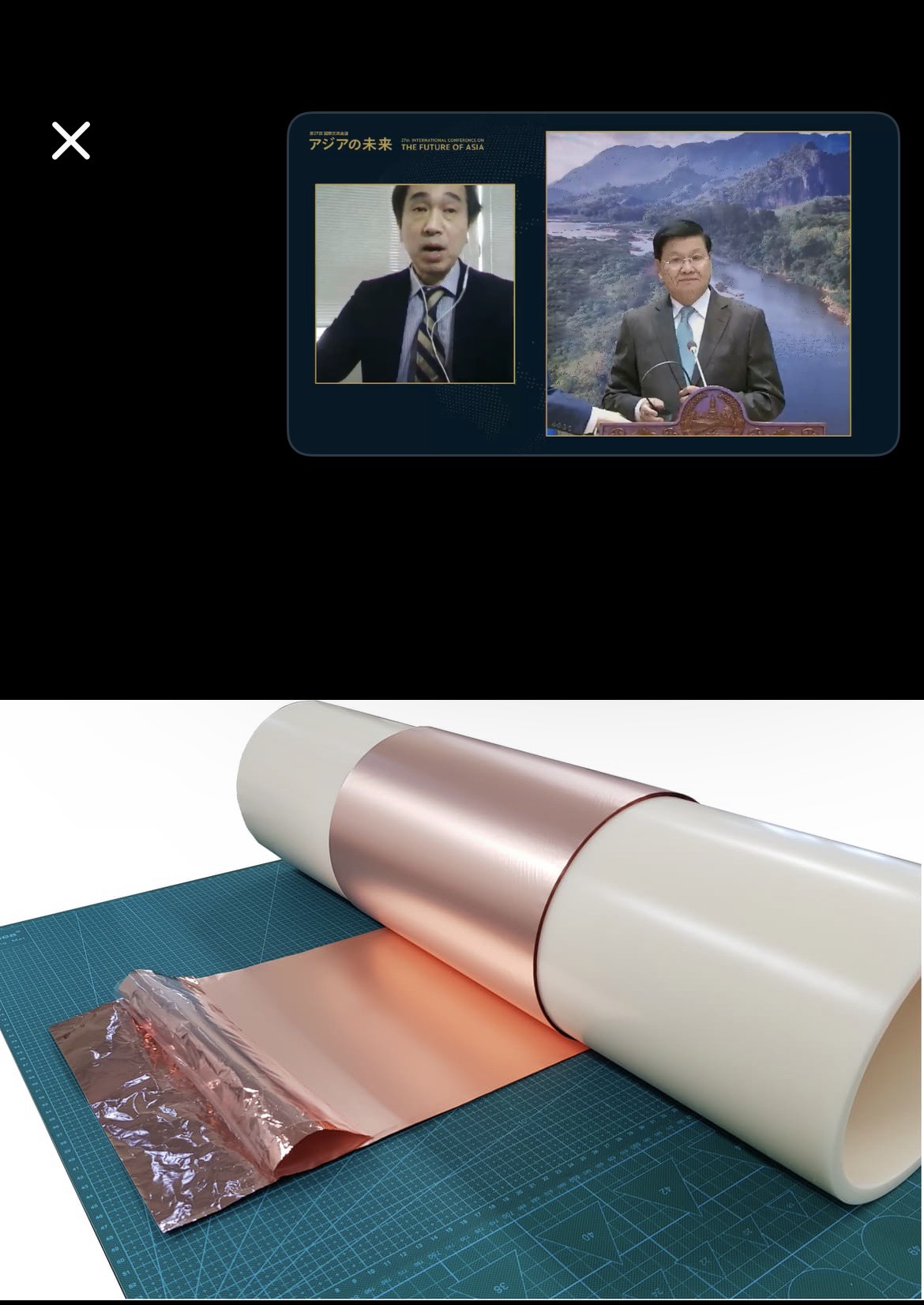

President Nagashima of STEC explaining the plasma irradiation device

STEC (Matsue City), an industrial machine, is embarking on the practical application of high-performance printed circuit boards for next-generation communication equipment. Fluororesin and copper foil are joined by plasma irradiation without using an adhesive, and we have recently succeeded in developing mass production technology. It is said that it can support the high-speed communication standard "5G" that is being developed and "6G" beyond that. With a policy of contract production of plasma-irradiated materials, we will encourage substrate manufacturers to adopt them.

The company has developed a unique plasma irradiation device that uses a special power supply and electrodes. For about three years, we have been researching printed circuit boards for electronic circuits that can be incorporated into communication equipment using this device. The focus was on the substrate with fluororesin and copper foil bonded together.

Most of the boards currently used for 5G communication equipment are made by adhering copper foil and liquid crystal polymer (LCP). In the future, in order to further improve the performance, it will be necessary to bond fluororesin or the like with less transmission loss to the copper foil instead of LCP. However, fluororesin has the property of being difficult to stick to other materials, which was difficult.

Significant cost reduction can be expected by rolling

STEC has developed a technology to bond plastic films without using an adhesive by causing a chemical reaction on the adhesive surface of the material by irradiating it with plasma. By applying this, we succeeded in adhering copper foil and fluororesin.

In the conventional method used by other companies, the surface is intentionally made rough to make it easier to stick, and then crimping is performed by using an adhesive, but such roughening treatment and adhesive are not required. It is also a big feature that it can be made with commercially available fluororesin film (PFA) and copper foil instead of a special material.

It is expected that next-generation communication equipment will require the use of radio waves called "millimeter waves," which are higher frequencies than those currently used and have a frequency of 30 to 100 GHz. When we commissioned a research institute in Tokyo to experiment with the company's prototype at 80 GHz in the millimeter-wave band, the transmission loss per 100 mm of material was minus 2.89 decibels. "The world's highest level of performance among fluororesin-based substrates that are considered to have high performance" (President Masatsugu Nagashima).

The company not only crimped fluororesin and copper foil to a flat plate, but also succeeded in finishing it in a roll shape. Rolling was easy to wrinkle and difficult, but it was realized by devising temperature control. "By making it into a roll, mass production is possible, and we can expect a significant cost reduction (compared to a flat plate)," says President Nagashima.

A machine that bonds a fluororesin film and copper foil into a roll

The company has invested about 150 million yen to install a clean room and four plasma irradiation devices in a part of the head office factory in Matsue city. After the completion of this summer, it is expected that plasma irradiation will be possible on a film of about 3600 square meters per day.

The company manufactures such plasma-irradiated fluororesin films on a contract basis and sells them to domestic and overseas substrate manufacturing companies. Since the roll-shaped machine can be sold or modified from an existing machine, the technology will be licensed for a fee, and the manufacturer will have the finished printed circuit board finished.

In addition to next-generation communication equipment, President Nagashima says, "High-speed communication is necessary to realize autonomous driving of vehicles, which is being researched in the world, and there should be demand for such applications." STEC was founded in 1991. Sales for the fiscal year ending September 2021 are approximately 800 million yen, and the company aims to achieve sales of 1.5 billion yen in the next few years.