T.RAD (Shibuya-ku, Tokyo), a heat exchanger manufacturer, is working on the development of a hot spring power generation system using thermoelectric power generation. The system will be installed at the hot spring inn “Yumura Onsen Midoriya” in Shinonsen Town, Hyogo Prefecture, which opened on April 1, and a demonstration test will begin

.

.

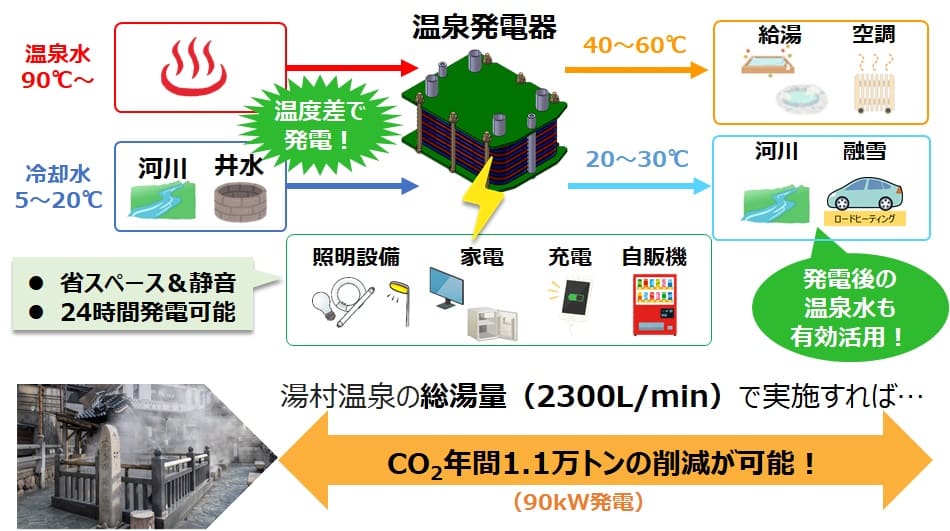

Thermoelectric power generation is a power generation method that uses the Seepek effect, which converts heat into electric power when a temperature difference is applied to a thermoelectric element. It is expected to be put into practical use as exhaust heat recovery and renewable energy, such as being able to operate 24 hours a day without noise.

The hot spring power generator currently under development uses 200 commercially available Peltier elements and is made compact by making it a laminated structure of "hot water layer - thermoelectric module - cold water layer". With a temperature difference of 65 degrees (assuming the temperature of the Yumura hot spring source in summer is 90 degrees and the cooling water is 25 degrees), approximately 100 W of power can be generated.

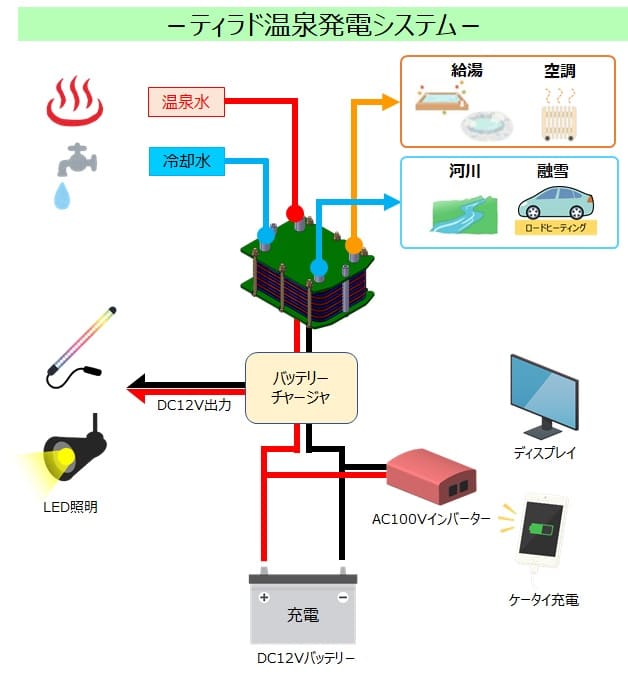

The hot spring power generation system used in the demonstration test uses one of these hot spring power generators to generate power using hot spring water and tap water. The generated power is charged in a 12V storage battery and used for power equipment such as displays by an AC100V inverter.

Various data such as power generation output and hot spring temperature information can be monitored remotely from the main unit, and the data is saved on the cloud. System control such as flow rate adjustment is also possible. In addition to this, hygiene aspects such as whether the hot spring water after power generation can be used for bathing will also be confirmed.

According to the company's calculations, if the total amount of hot water in Yumura Onsen is 2,300 liters per minute, and the total amount is 90 degrees Celsius, the power output of a system that connects multiple hot spring power generators will be 90 kW, which can reduce CO2 emissions by 11,000 tons per year. Since it can generate electricity 24 hours a day without noise even at low output, it can be used as an emergency power source by charging a storage battery.

In the future, with the aim of commercializing hot spring power generation, we will search for hot spring areas suitable for thermoelectric power generation and work with hot spring resorts and hot spring inns on power generation verification tests of the system. In addition to hot spring power generation, we will also work to expand the application of thermoelectric power generation technology such as exhaust heat recovery.