Obayashi Corporation is introducing various efficient construction tools for construction related to the 2025 World Expo (Osaka/Kansai Expo). Using DX tools to manage construction vehicles and workers, understand construction progress, etc. As many as 5,000 workers will be working every day on the entire Expo construction project, so the project will not only facilitate on-site work but also help manage workers and ease traffic congestion in Yumeshima (Konohana Ward, Osaka City), where vehicle access is limited.

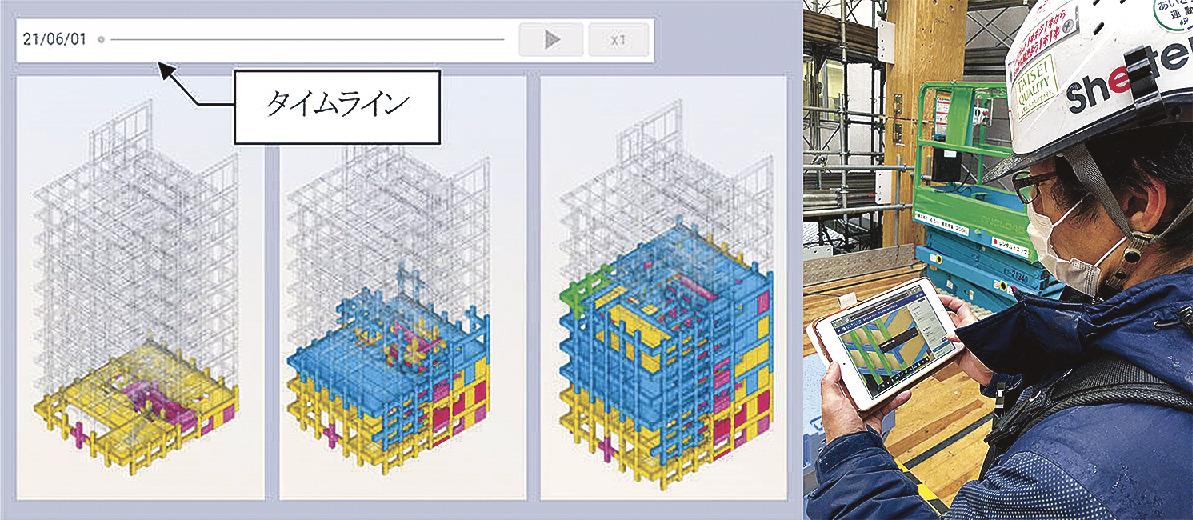

Promie can display construction progress status by color (from Obayashi Group homepage)

The ''construction vehicle management system'' introduced will facilitate on-site work, prevent congestion on surrounding roads caused by construction vehicles, and reduce vehicle waiting time. When transporting materials or equipment, please register the vehicle license plate and other information in advance with your smartphone. Please adjust in advance so that the vehicle is not concentrated. The AI camera will read the license plate and only pre-booked vehicles will be allowed to enter.

The facial recognition entry/exit system has also been applied to manage the entry and exit history of workers. Workers are registered in the system regardless of which gate they enter or exit from. In addition to being used to track the number of workers, this information is also registered in the Construction Career Promotion System (CCUS) as the worker's work history.

Promie, a progress management application that uses a 3D designed web model for construction management, is a tool developed by Obayashi Corporation. We manage 12,000 units of wood used to build a large roof ring, from transportation to the construction site, delivery to the construction site, and assembly at the construction site.

The construction of the "Women's Pavilion", which will be exhibited by Cartier Japan (Chiyoda-ku, Tokyo, President and CEO Jun Miyaji), the company that operates the jewelry brand "Cartier", will be held at the Japan Pavilion at Expo 2021 and 2022 in Dubai to precisely assemble about 8,000 metal parts used in the project, two-dimensional codes are attached and managed by Promie.

Autonomous drones are used to assess conditions over large areas. Ground images taken daily from a programmed route are converted into point cloud data. By continuously sharing the latest images and point cloud data, progress can be checked and dimensions can be measured from a remote location.

Using the "CONNECTIA" application, which uses digital twin technology for construction management. A 3D designed web model is placed on the point cloud collected by an autonomous drone using Connectia. By setting up transportation routes and arranging heavy machinery on the digital twin, it is useful for accurately simulating construction work.

Invite partners to watch the activities of Pacific Group Co., Ltd.

FanPage: https://www.facebook.com/Pacific-Group

YouTube: https://www.youtube.com/@PacificGroupCoLt