The New Energy and Industrial Technology Development Organization (NEDO) and Sumitomo Osaka Cement have successfully developed and tested a “next-generation low-carbon semi-flexible pavement”. Developed under the NEDO Green Innovation Fund project, it reduces carbon dioxide (CO2) emissions by approximately 58% over the entire life cycle (LC), from cement production to construction, use, and disposal, compared to conventional semi-flexible pavement. NIPPO cooperated in the development. We will continue to conduct test construction and development efforts with the aim of improving the CO2 reduction rate.

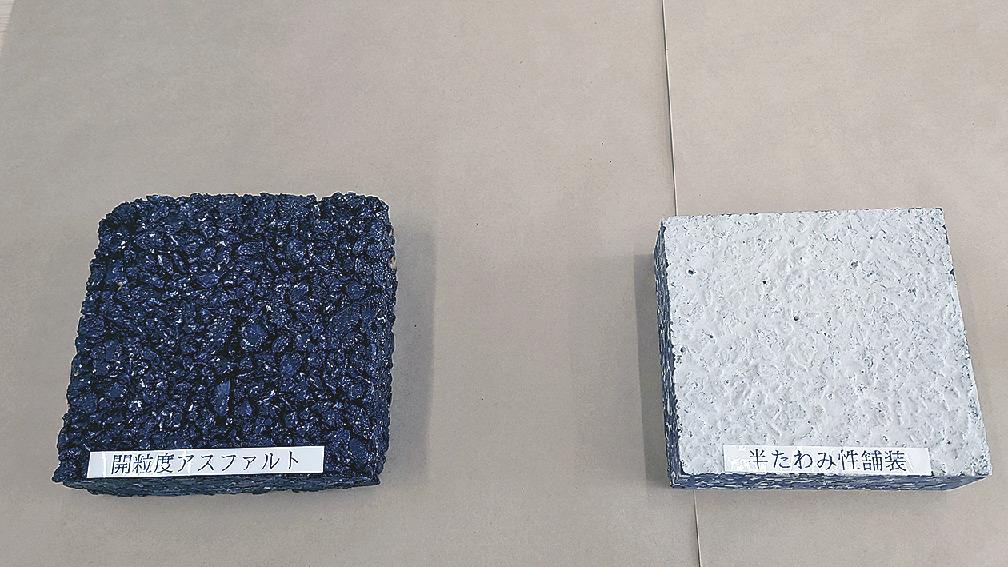

Developed semi-flexible pavement (right) and conventional open-grain asphalt

Sumitomo Osaka Cement made the announcement at a press conference in Tokyo on the 18th. The new technology reduces the clinker ratio in the cement of semi-flexible pavement cement emulsion by 30 to 40%, reducing CO2 emissions. It will also be fixed with artificial limestone made from calcium-containing waste and CO2 from cement plant exhaust gas. Artificial limestone is used as a filler in carbon-recycled cement for semi-flexible pavement cement emulsion and as an aggregate in open-grain asphalt mixtures.

By increasing the carbonation reaction by more than twice that of conventional products, the amount of CO2 fixed during both the pavement construction and service phases is also improved. After the end of its 20-year service life, it will be dismantled and reused as a road base material. The fixed atmospheric CO2 inside the semi-flexible pavement is fixed semi-permanently.

Sumitomo Osaka Cement estimates that more than 500,000 square meters of semi-flexible pavement are built each year in both the public and private sectors in Japan. It is estimated that by replacing all of this with the newly developed pavement, CO2 emissions could be reduced by 2,000 tons per year, or 40,000 tons over 20 years. It is estimated that 130 tons of carbon could be removed per year, or 2,600 tons over 20 years.

At a press conference on the same day, Noriyuki Kosakai, Executive Director, Director of the Cement and Concrete Research Institute, and Director of the Sustainable Development Promotion Office, emphasized: ``The next-generation low-carbon semi-flexible pavement is the first of its kind in the world, and it will be a technology that Japan can promote. ’’ did so.

Invite partners to watch the activities of Pacific Group Co., Ltd.

FanPage: https://www.facebook.com/Pacific-Group

YouTube: https://www.youtube.com/@PacificGroupCoLt