Mitsubishi Jisho Sekkei has developed a production system using 3D printing technology on wood. Through efforts ranging from architectural design, interior design to construction, we have created a 3D printed wooden building that we position as a prototype. This project is an effort to recycle resources by turning waste into recyclable materials by using wood pulp generated during the sawing process as a plastic material (filament) for casting, which is used as a material for 3D printers. According to the company, this is the world's first 3D printed wooden building.

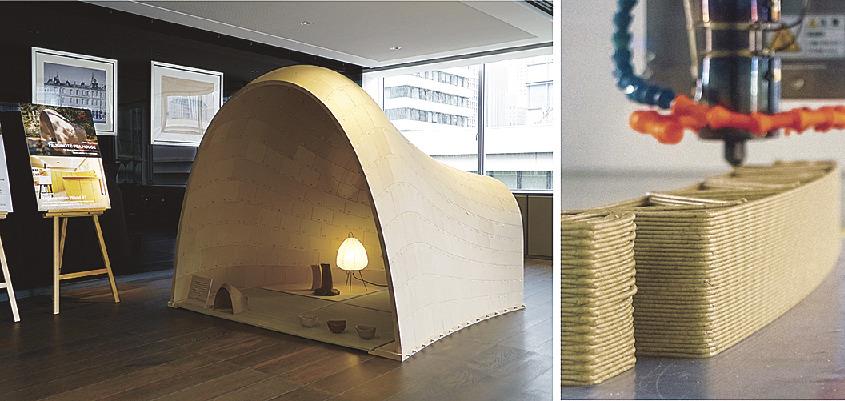

Exhibition and 3D printing ((c) Mitsubishi Jisho Sekkei)

“Regenerated Wood” is developed using a unique wood-based 3D printing material. By using trees near the project site to reduce the carbon dioxide (CO2) emissions created when transporting raw materials, and by reducing the size of the output components and assembling them by hand, the entire manufacturing process can be improved.

As a demonstration prototype, the company created a 3D printed wooden building called "TSUGINOTE TEA HOUSE", which is currently on display at the company's main store in Chiyoda-ku, Tokyo.

We are also launching the "Regenerated Wood #1" partition produced using the same system. It can be divided into small, lightweight parts, transported and assembled by a small number of people. High-precision joints eliminate the need for hardware. In the filament production process, we cooperate with MEC Industry (Yusui-cho, Kagoshima Prefecture, President: Hideo Ono) and receive wood powder.

Invite partners to watch the activities of Pacific Group Co., Ltd.

FanPage: https://www.facebook.com/Pacific-Group

YouTube: https://www.youtube.com/@PacificGroupCoLt