Kajima / Tunnel -covered and medium -class concrete is also fully installed, first introduced in actual construction

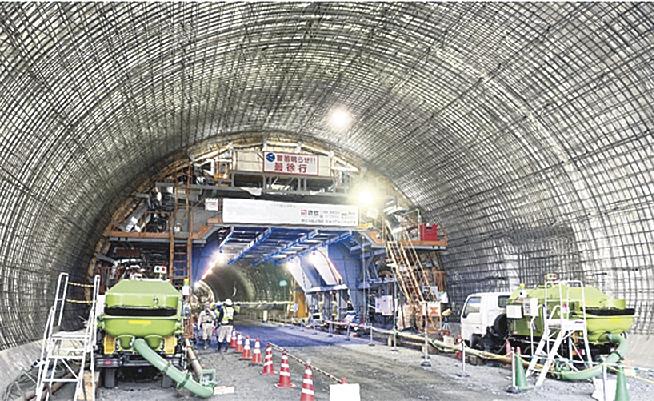

Otsu Oishi Tunnel "Fully automatic tunnel -covered concrete concrete casting system" all scenery (from news presentation materials)

Finishing status of coating concrete after removal (from news presentation materials)

Kajima is a "fully automatic tunnel -losing concrete concrete system" jointly developed with Gifu Kogyo (Mizuho City, Gifu Prefecture, Munakata National President), which designs and manufactures tunnel construction machinery on the 7th. It was announced that it was introduced for the first time. A complete automatic casting system with a high -flow concrete for coating that does not require tightening in 2020 has been improved so that it can be used for a lighter -tight coating concrete that requires minor tightening. The middle -class mobilized concrete concrete can be fully placed at high speed, achieving productivity and quality improvement.

The new system was developed by three companies, Kajima, Gifu Industry, and Sintech (Kochi City, President Tomomi Tadokoro). A casting control device that links two concrete pumps to the conventional system and a complete automatic control device of a formwork vibrator has been added as a new function.

In order to install a large amount of coasting concrete in a large amount and high -speed (200 cubic meters per day), one concrete pump is deployed on the left and right. A plurality of sensors installed on the surface of the formwork detect the rising height of the concrete, and automatically switches the discharge of each pump and controls it. It can always be placed while keeping the same height left and right.

All formal vibrators installed in advance were automatically controlled, eliminating the need for people. The timing and duration of operation are made into patterns and set in advance. In conjunction with the casting control device, the concrete is automatically tightened according to the rising height of the concrete.

The first introduction site was the "Shin -Meijin Expressway Otsuishi Tunnel Construction" (Otsu City) ordered by the West Japan Expressway Kansai branch office. Compared to conventional methods that require human power, the average rate of casting speed has been increased by about 15 % and man -hours have been reduced by about 50 %.

In the future, Kajima will expand the system widely to other construction and verify further rational construction. In the future, he wants to build an integrated system that automatically performs work processes from formal frames to concrete placement and curing.