The three parties, including the East Japan Expressway Kanto Branch, will begin construction of the light tunnel in the project area south of the Tokyo JCT Outer Ring Road Hub. Of the two tunnels to be built, excavation of the vehicle tunnel to Tomei JCT will begin from this month onwards, as soon as preparations are completed. Construction of the tunnel for vehicles traveling to Chuo JCT will begin in spring 2024.

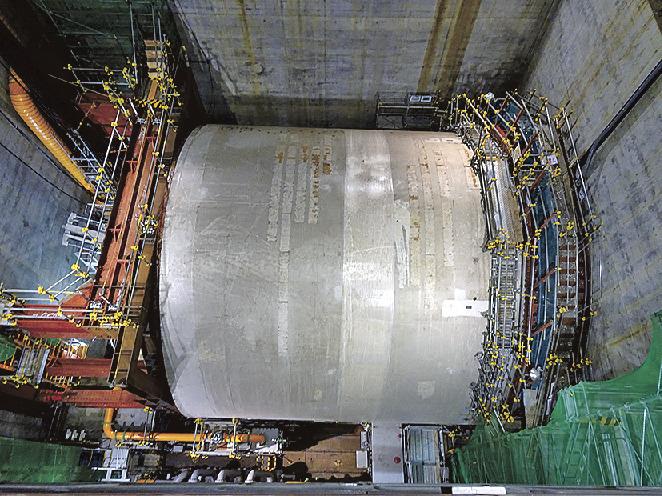

The machine shield is installed on the starting shaft

In addition to the East Japan Expressway Kanto Branch, the implementing units of the outer ring road development project are the Tokyo Central Expressway Branch and the Kanto Regional Development Bureau. During construction, thorough measures will be taken to prevent a recurrence, including a detailed understanding of the amount of soil taken in by the shield machine, taking into account the cave accident that occurred in Chofu, Tokyo in 2020.

Tips of the shield machine

This construction section is Kitano-Nakahara, Mitaka City, Tokyo. A mud pressure barrier with an outer diameter of about 12 meters will be used to build a “ramp” connecting to the main line running about 40 meters underground. Each tunnel has two lanes. No completion date has been set as construction will proceed with the safety of the surrounding area as the top priority.

The company building the tunnel where vehicles will go towards Tomei JCT (light shield tunnel construction B) is a joint venture between Obayashi Group, Fujita Group and Iwata Jizaki Construction Company, which will dig the length about 1,080 meters. The construction of the tunnel (light shield construction F) where vehicles go towards Chuo JCT will be approximately 720 meters long and will be handled by the Obayashi-Omoto-Zenitaka joint venture.

During construction, this will prevent soil compaction, which caused the cave accident in Chofu City. During excavation, it is necessary to closely monitor whether the soil has plastic fluidity or not. If there are concerns about ensuring the fluidity of the resin, such as when work is suspended for a long period of time, the type and amount of additives added can be changed. To prevent excessive soil absorption, the weight control value of excavated soil has been tightened. Early detection of abnormal signs.

The three sides released the light shield launch shaft to the press on the 14th. A shield machine was installed in a rectangular pit with a depth of 20 meters. Tunneling for light shield B will begin after completing the installation of electrical equipment and conveyors behind the machine. About 490 cutters rotate at the machine head to scrape the soil. Excavated soil will be collected in pits at the shaft area and then transported by truck.