Started development of a demonstration unit for the Green Ammonia Production Ship "GAPS"

Aizawa Koatsu installs a fuel production module on a 10MW-class offshore wind power full concrete floating body

To build a green hydrogen supply chain derived from offshore wind power

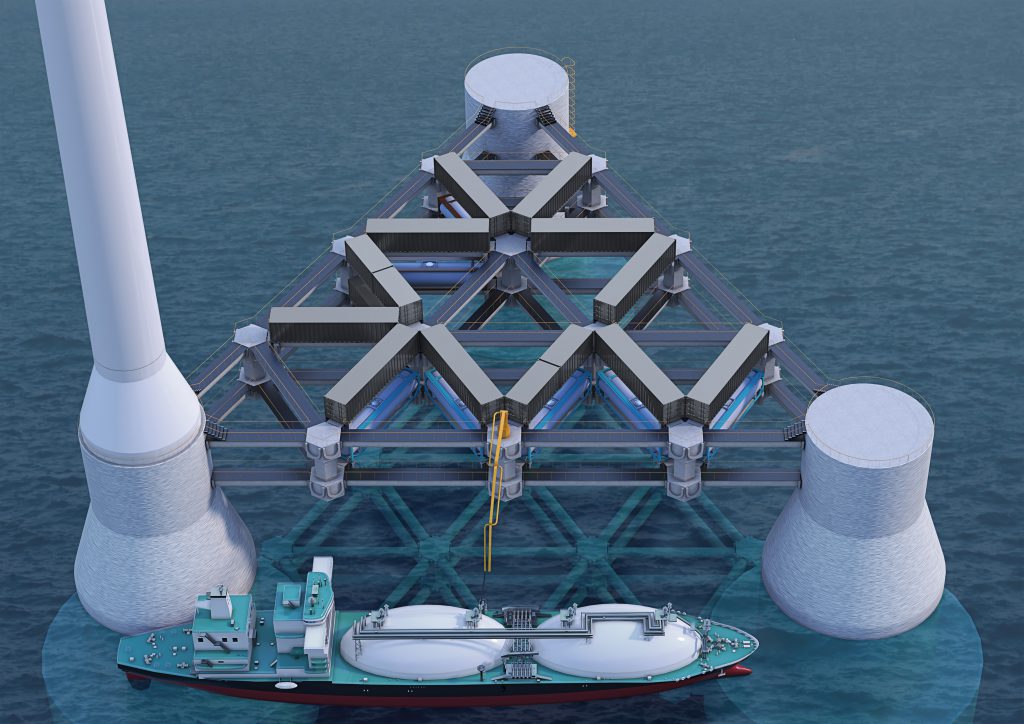

Aizawa Koatsu Concrete Co., Ltd. (headquartered in Tomakomai City, President: Yoshihiro Aizawa) has installed an international container-type ammonia production module in a full-concrete semi-sub-type floating body that supports a huge 10MW-class offshore wind tower. We have embarked on the development of a demonstration model of the "Green Ammonia Production Ship" (development code: GAPS), which will be installed and directly produce and store green ammonia on the sea.

Starfire Energy Inc. of Denver, Colorado, USA, which has technology to produce green ammonia from electricity, water, and air at low pressure and energy saving, and Syzygy Plasmonics Inc., of Houston, Texas, USA, which has catalyst technology to convert ammonia into hydrogen with extremely low energy. , respectively. Renewable energy derived from offshore wind power is temporarily converted into green fuel, transported, fuel cell grade green hydrogen is generated just before use, and supplied to FCV fuel cell vehicles. The aim is to build a chain model.

Green ammonia production ship GAPS first ship "MIKASA"

■ Green hydrogen is ideal, but cannot be transported

Ammonia (NH3), like hydrogen, emits no CO2 when burned and has a higher energy density than lithium-ion batteries or compressed/liquid hydrogen, making it a promising green fuel that can replace petroleum. In addition to being used directly as a fuel, it can also be converted to hydrogen (H2). expected as a career.

Most of the wind power generation currently planned is assumed to be used by connecting it to the grid of the electric power company. A low-cost, safe, and highly feasible hydrogen supply chain should be built that converts hydrogen into fuel, stores it in tanks, transports it by land and sea, and converts it to fuel cell-class hydrogen just before use. I think.

Hydrogen itself is the ultimate green energy, but a realistic method for transporting and using it safely and smoothly has not yet been established. .

By adopting the method of using ammonia produced by offshore wind power as a hydrogen carrier, (1) electric power can be constantly stored as fuel without worrying about fluctuations in the output of wind power generation (continuously producing fuel on the sea for 24 hours). Green offshore oil field) 2. Costs related to hydrogen transportation can be reduced to about one-seventh, and a low-cost, safe and stable hydrogen supply chain can be built in dispersed demand areas 3. Pressure rise in hydrogen service stations (SS) It eliminates the need to store large volumes of hydrogen, making it possible to reduce the size of hydrogen SSs to the size of current gas stations, and the hydrogen filling time, which has been an issue, can be reduced to the same or shorter time as gasoline refueling. there is.

We believe that we should urgently create a diverse and well-balanced energy supply network in which "electricity" and "fuel", and "grid" and "off-grid" coexist and complement each other. We are confident that this new hydrogen supply chain will become a “thin energy” that paves the way for energy self-reliance and decarbonization in Japan that does not rely on fossil fuel imports.

A special purpose company (provisional name: Shin-Energy Inc.) will be established soon for the development of GAPS demonstrator and prototyping of ammonia and hydrogen production modules, and we will proceed while seeking investors and partners from domestic and overseas business companies. . A large number of green ammonia production ships with huge 10 MW windmills will float in Japan's territorial waters. It is an idea to develop a demonstration machine based on

■ Floating body structure of "MIKASA" making full use of advanced concrete technology

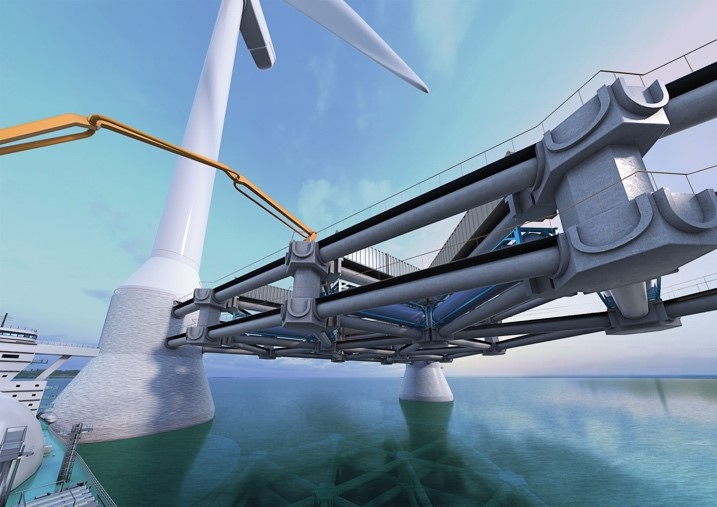

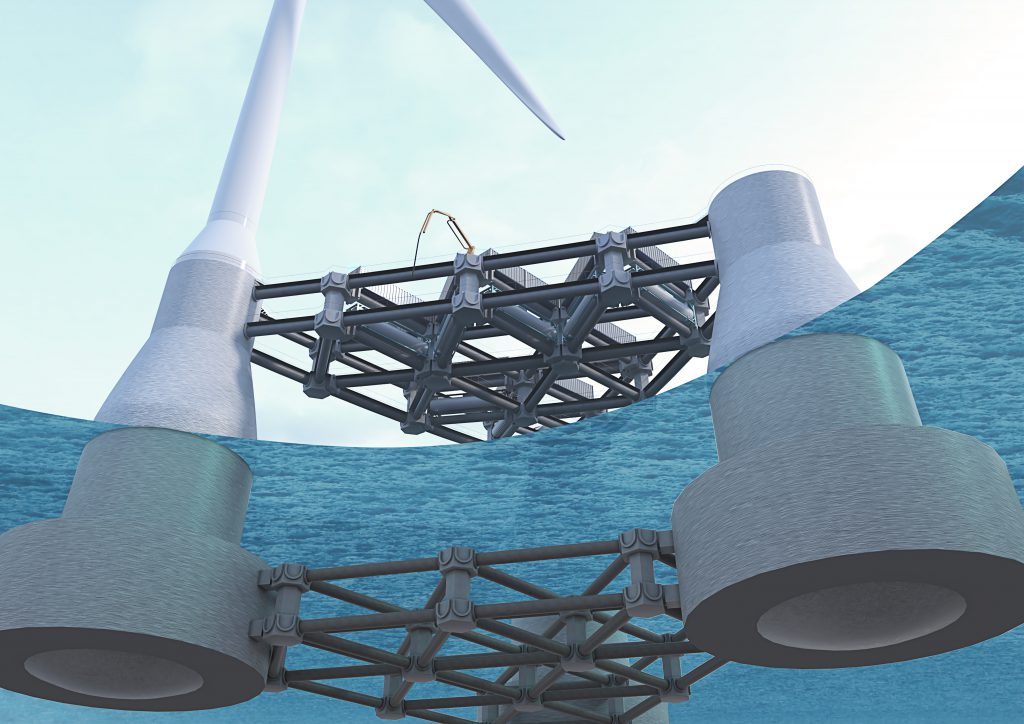

MIKASA is a huge semi-submersible floating structure with concrete floaters arranged at the vertices of an equilateral triangle with a side length of 68m. It is unique in that international container-type ammonia production modules are mounted on super-large-diameter pile beams that serve as connecting members. It's a design.

The floater part is a cylinder with a diameter of 18m and a height of 42m, and a heave plate with a diameter of 28m. A concrete 3D printer laminates the wall frame and then fills and integrates the structural concrete, so there is no need for a steel formwork, shortening the construction period and reducing costs. In order to improve the performance of the floating body, the inside of the wall frame is filled with lightweight concrete, and the bottom is made convex to create a structure that can withstand strong water pressure.

GAPS is a semi-submersible floating body with all members made of concrete.

A large force acts on the floater due to wind and wave forces. To resist that force, a post-tension prestressing method is used to compress the concrete vertically, preventing the floater from cracking. In addition, the self-healing concrete "Basilisk HA" (NETIS registration number: HK-220003-A), developed by our company that automatically repairs cracks with the metabolism of bacteria, further ensures the safety of the floating body.

Floater shape

For the beam members that connect the three floaters, ultra-large PHC piles (Pretensioned Spun High Strength Concrete Piles) with a diameter of 1,200 mm, which are capable of standard mass production, are used. By arranging PHC piles and joint members made of precast concrete in a grid pattern and applying prestress in all directions, a strong and huge floating body model is constructed.

φ1,200 PHC pile used as a connecting member (Bibai Factory)

By using full concrete for the floating body members, materials can be supplied from all over the country, and dock construction is easier than building base ports for steel floating bodies, leading to mass production of floating bodies.

■ Starfire Energy

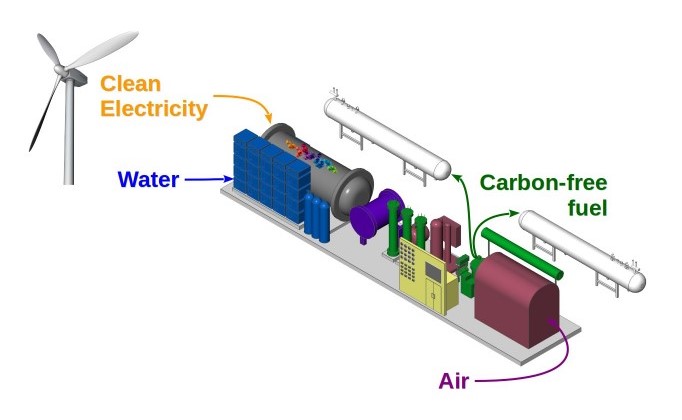

MIKASA's green ammonia production module is being developed in collaboration with Starfire Energy Inc., a startup company in Colorado, USA. Starfire's Green Ammonia Reactor can handle fluctuating power from wind power, and its innovative catalyst technology, unlike the conventional Haber-Bosch method, converts 1 kg of green ammonia into 14 kWh, including electrolysis of water. It can be manufactured with very little electricity.

Starfire Ammonia Reactor

Starfire Ammonia Reactor

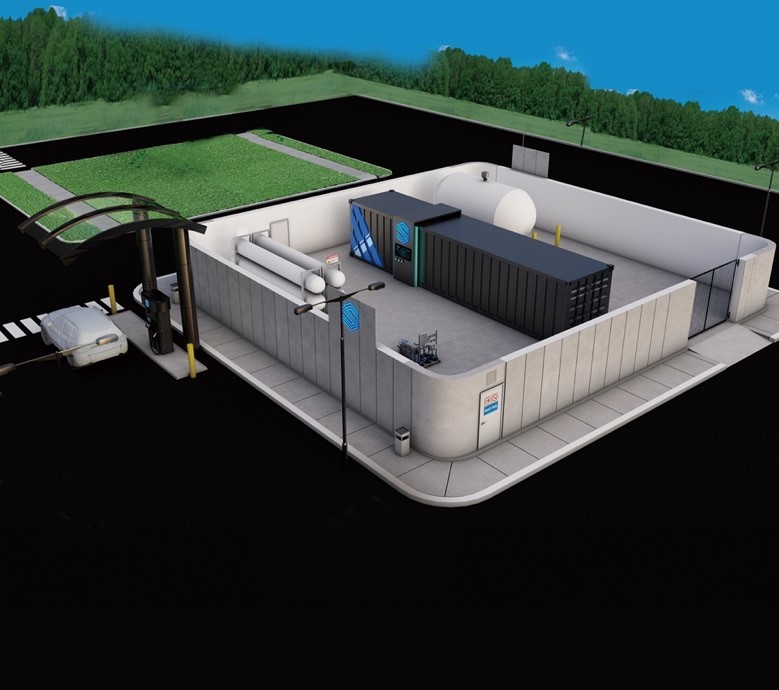

This system consists of a total of 10 types of containers, including an ammonia reactor: an RE container, a hydrogen production device that is the raw material for ammonia: an H2 container, a nitrogen production device: an N2 container, and a seawater purification device that is the raw material for hydrogen: an RO container. Configured and pre-wired and plumbed for easy interconnection of each container on site.

Starfire Containerized Ammonia Production Module

Assuming the installation of a 10MW class wind turbine, MIKASA's green ammonia production capacity is approximately 1,700 tons per year. Six storage tanks of 50 kℓ are arranged, and storage for about 40 days is possible.

\

■Syzygy Plasmonics

In order to efficiently extract hydrogen from ammonia transported on land, we partnered with Syzygy Plasmonics Inc. in Houston, Texas, USA, to develop a compact compact system that uses a state-of-the-art photocatalytic reactor to produce fuel-cell-class hydrogen from ammonia with extremely little energy. We are proceeding with the development of a next-generation hydrogen SS (service station) demonstrator.

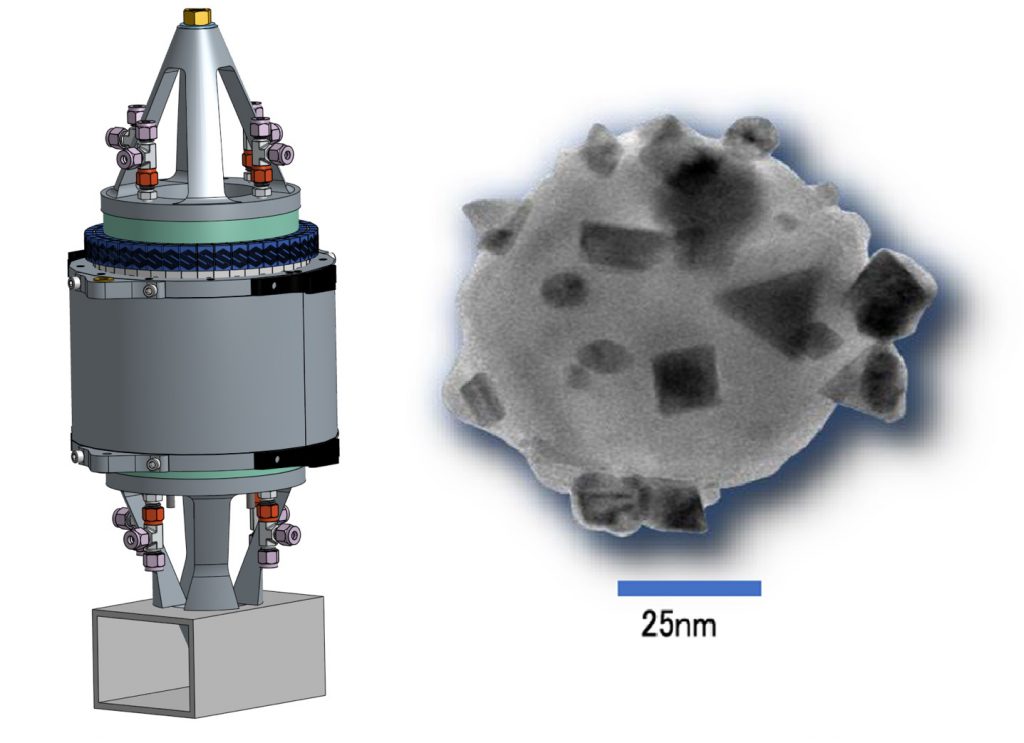

Image of Syzygy photocatalytic hydrogen reactor system

The LED photocatalyst technology called “antenna reactor”, which combines conventional catalytic nanoparticles (reactor) and larger light-harvesting plasmonic nanoparticles (antenna), converts 1kg of hydrogen to just 23kWh of electricity. It has been demonstrated to convert from ammonia with a high purity of 99.999%. This is an astonishing 20% or less power saving compared to hydrogen production methods that use electrolysis of water, and is completely different from large plants equipped with internal combustion engines such as thermal power plants, making it compact and environmentally friendly. This will pave the way for a decentralized hydrogen production system.

TEM image of LED photocatalytic reactor and photocatalytic nanoparticles

■ Distributed hydrogen supply chain created by offshore wind power and ammonia

The green ammonia produced onboard the GAPS is collected and transported by an ammonia carrier with a deadweight of 1,000 tons and stored at the nearest port. The ammonia tanker transports the fuel as it is to the hydrogen SS, and just before it is used, it is converted into hydrogen in Syzygy's advanced reactor and supplied to FCVs and FC forklifts.

We will build an offshore and off-grid type energy value chain that is unparalleled in the world by linking ammonia and hydrogen production module technology backed by innovative catalyst technology with full-concrete large-scale floating body technology. increase.

A hydrogen supply chain model using ammonia as a hydrogen carrier

■ On land, PC hybrid wind tower construction method "VT"

On the other hand, for onshore wind power, the 80m-class steel wind tower will be raised to a 120m-class prestressed concrete (PC) tower, increasing the power generation efficiency of each tower by more than four times. Ventus Turris” (commonly known as VT) is being put into practical use.

Structure of VT

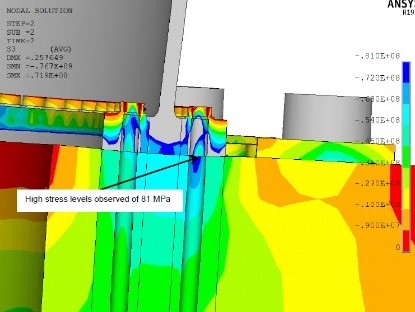

Since April 2020, we have completed a mass model of a 5.8 MW generic wind turbine (rotor diameter 155 m) with the cooperation of major overseas wind power equipment manufacturers, and we are one of the world's three largest certification bodies. We have started the structural analysis required for design certification with the DNV Foundation (headquartered in Oslo, Norway), and verified the maximum stress generated by horizontal force during typhoons and earthquakes and the location where it occurs. Looking ahead to the full-scale popularization of the next-generation model 120m-class tower (late 2020s), we will cooperate with electric power companies, wind power generator manufacturers, and construction companies to develop details for the construction of demonstration equipment. We are planning to enter the design phase.

FEM analysis result

In addition, Aizawa Koatsu Concrete, a comprehensive concrete manufacturer based in Hokkaido, the mecca of onshore wind power, not only designs and manufactures PC components for VT, but also has a pile-dedicated factory that can only supply φ1,200 super-large-diameter piles in Hokkaido. We also design and manufacture flume products for power transmission and box culverts for tunnels, and provide total solutions for wind farm construction, including grid maintenance.

AIZAWA's total solution

■ Exhibiting at WIND EXPO Fall 2022, an international wind power exhibition starting tomorrow

We will be attending the 2nd WIND EXPO Fall 2022 - [International] Wind Power Generation Exhibition -, an international exhibition on wind power generation technology, which will be held at Makuhari Messe for three days starting tomorrow, August 31st (Wednesday). I will exhibit. At the venue, we will introduce the first green ammonia production ship GAPS "MIKASA" and the PC hybrid wind tower construction method "VT" while viewing panels and videos. We look forward to seeing you there.

■ About Aizawa High Pressure Concrete

Based on the philosophy of Innovate, Challenge and Trust, we are a comprehensive concrete manufacturer that works to create new corporate value by combining concrete materials and cutting-edge technology. Self-healing concrete (Basilisk) that repairs cracks by itself using the metabolic function of bacteria and quick-drying cement

Leveraging industry-academia collaboration with MIT and Delft University of Technology, etc., we will quickly launch new innovations such as concrete 3D printers using materials from the traditional materials industry, and innovation marketing centered on smart materials from the traditional materials industry. We are setting up DX to the group. Net sales (non-consolidated) for FY03/22 are 20.3 billion yen. 647 employees.

(Inquiries regarding this press release)

■ Aizawa High Pressure Concrete Co., Ltd.

Development Sales Headquarters PC Technology Supervisor: Kenji Yamamoto (080-2863-4147)

■ Aizawa High Pressure Concrete Co., Ltd.

Development Sales Division Strategist: Katsushi Maeda (080-2863-4126)

■ Director of Aizawa Technical Research Institute: Ryo Aoki (080-2863-4151)