"Repowering" of solar power plants will change! Replacing power conditioners from centralized to decentralized

Some power plants have reached the turning point of the FIT period, and the momentum for "repowering" is increasing. The point is to review the power conditioner. By replacing the centralized type with the decentralized type, it will be possible to increase the amount of power generation and reduce O & M costs. We approached Huawei's repowering solution.

Increase power generation by repowering

The key is to move to distributed power conditioners

Solar power plants have been rapidly introduced since the start of the FIT system in 2012. The market environment has changed significantly in the last 10 years, and some power conditioner manufacturers have withdrawn from the Japanese market. The lack of maintenance and after-sales service has become a pressing issue for power generation companies using these power conditioners. If the power conditioner breaks down, replacement parts are out of stock and there are no staff who can repair it immediately, so power generation will not be possible for a long time and a large loss will be incurred.

In addition, many power plants that started operation at an early stage are suffering from a decrease in power generation and an increase in maintenance costs. At the same time as the replacement of the power conditioner, there is a growing movement to review the entire power plant system and increase the amount of power generation (repowering).

In repowering, all equipment at the power plant will be considered for review, but the most important and effective one is the replacement of the power conditioner. Most of the solar power plants built early, in particular, use centralized power conditioners, which were the mainstream at the time. Today, even in cases where distributed power conditioners are used, centralized power conditioners are installed, and the disadvantages are becoming apparent in combination with aging deterioration.

In such a power plant, a large repowering effect can be obtained by replacing the centralized power conditioner with the latest distributed power conditioner. However, in order to make the centralized type decentralized, it was not easy because it was often necessary to remodel the entire power plant, such as re-laying the wiring cables inside the power plant.

Optimized for migration from centralized

Power conditioner for repowering

Huawei's power conditioner for repowering is attracting attention as a solution to these problems and enabling the transition from centralized to decentralized. Although this product is a distributed power conditioner, it can be replaced with a centralized power conditioner from another company, and modifications related to the entire power plant can be minimized. The entire system can be rebuilt without modifying the wiring cables on the DC side.

Furthermore, with this power conditioner dedicated to repowering, there are no restrictions on the output voltage of the existing power conditioner. Even existing power conditioners other than the standard 210V and 420V can be replaced without any new modifications. In the past, power conditioners had various output voltages, so the merit of being able to handle anything is great.

According to Huawei, replacing the traditional centralized power conditioner with this product can increase power generation by more than 4%. At the same time, maintenance costs can be reduced by more than 50%.

Construction example of SUN2000-20KTL-M3

Construction example of SUN2000-20KTL-M3

Power conditioner for repowering-scheduled to be released in October (62.5 / 83.3 / 100kW)

Supports a variety of repowering

Contributes to O & M cost reduction

Depending on the power plant, it is possible to utilize the existing Huawei distributed power conditioner (multi-MPPT type) for repowering without using new products. Due to the above-mentioned restrictions on the output voltage, there are cases where it cannot be dealt with or major modifications are required, but if the conditions such as specifications are met, a greater repowering effect can be obtained. It is easy to migrate from other companies' distributed power conditioners.

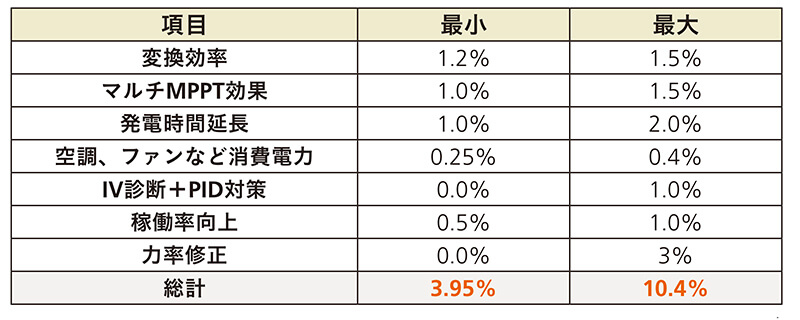

Since the power conditioner is equipped with a multi-MPPT circuit, it is expected that the amount of power generation will increase by 5% or more when replacing the single MPPT power conditioner. Huawei estimates that the effect can reach up to 10.4% (Table 1).

In this way, Huawei is responding to the rapidly growing repowering needs with a variety of solutions. All products have a low failure rate and are maintenance-free types with no regular replacement parts. The company's original smart IV diagnosis can identify the cause of failure, which contributes to a significant reduction in O & M costs. In the unlikely event of a failure, power sales loss can be minimized by replacing the product within 2 business days.

If you send information about the power plant to Huawei, it will suggest the best repowering for the equipment. The company also discloses a method for calculating revenue for repowering costs (Table 2). Even the power plants built early have only reached the turning point of the FIT power sale period. Given the long remaining period, there is no reason not to consider repowering.

Power generation increased by 3.95 to 10.4% by replacing with multi-MPPT power conditioner (Table 1)

Source: Huawei